Big Bag Recovery is the Australian Government Accredited Product Stewardship scheme for plastic bags over 15kg/l of contents (sacks and bulk bags). The program only includes recyclable bags that are woven polypropylene (wPP) and low density polyethylene (LDPE). The program allows for two sizes: sacks and bulk bags.

TAKING RESPONSIBILITY FOR OUR PACKAGING

Australia's current co-regulatory framework

Australia has a mandatory national co-regulatory framework for packaging.

It creates obligations for brand owners to design more sustainable packaging to increase recycling and reduce litter. Businesses with an annual turnover of $5 million or more that produce or sell packaging or packaged products in Australia can meet their obligations by:

Big Bag Recovery Impacts

7,638,334 kg

plastic recovered

11,211,546 kg

CO2e reduction

$19,095,834

landfill cost savings

76

circular economy jobs created

What is a big bag?

Big Bags are the bags that carry products and ingredients to all sectors of industry and our backyard. Things like: fertiliser, seeds, animal feeds, flour, salt, sugar, milk powders, sand, gravel, mulch, cement and more.

The Challenge

The impact of doing nothing per year

We did not generate the initial plastic or its problems, but we can influence what happens after that.

While it’s a shared responsibility to do the right thing with the plastic, it’s a regulatory obligation on the importers and brand owners to ensure this happens. More details below.

Most people are aware of the significant problem plastics can have on our environment. This is particularly true for packaging.

Not only does it cause significant harm, but it is also a resource that can be used in a positive way many times to improve the plastic impact.

Big Bag Recovery Benefits

Better environment for our planet and future generations

Cleaner water ways

Reduce the impact of climate change on the planet

New sustainable industry for the region

Jobs for the community

Saves communities $$$$ in landfill & environment costs

The Solution

Members

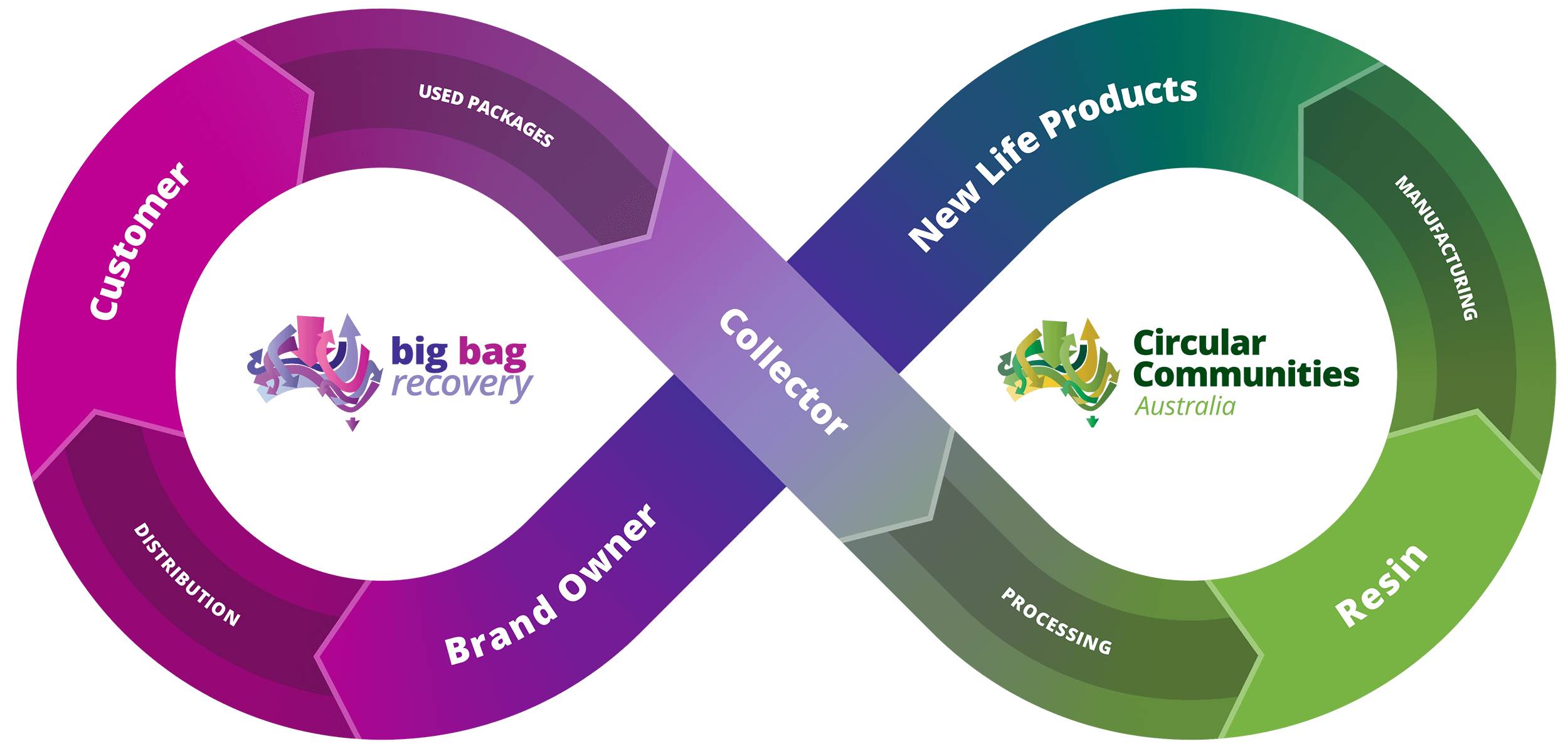

Our program provides the practical application for Importers and Brand owners of plastic packaging under the National Environmental Protection (used packaging) Measure 2011.

It provides our Members with the ability to report total provenance from when their packaging has been collected to where it is recycled into a new product. Our Members have live dash boards and will have video feeds of their bags being processed by Circular Communities Australia.

Responsibility

Regulatory

Social

Big Bag Recovery Data

We report on what is collected, when and where and the impacts this has on the environment CO2e, the community in landfill costs saved and jobs generated.

Frequently Asked Questions

What is Big Bag Recovery (BBR)?

Big Bag Recovery is the only Australian Government Accredited product stewardship scheme for plastic bags over 15 kg/l of contents (sacks and bulk bags). The program only includes recyclable bags that are woven polypropylene (wPP) and low density polyethylene (LDPE). The program allows for two sizes: sacks and bulk bags. Big Bag Recovery is bound to the terms of its accreditation. This includes a performance matrix and reporting. More information can be found on the Federal Government website. https://www.environment.gov.au/protection/waste/product-stewardship/products-schemes/big-bag-recovery

Why was BBR created?

The program was created by Industry Waste Recovery with the support of Industry, all State and Federal Governments, and consumers to provide a way to prevent environmental harm from plastic packaging and in doing so allow Brand Owners to meet their Regulatory and Social obligations.

Do I have to join?

No. The scheme is voluntary.

What if I do not join?

You run the risk of not meeting your regulatory and social obligations. You place unfair risk on your customers and, your packaging may not have an appropriate end of life solution. The waste export ban for plastic started in July 2021. Under the Recycling and Waste Reduction Act 2020, the Minister has the ability to name nonparticipants.

Whose responsibility is it? “I’ve sold it, it’s not my problem”.

Under the National Environmental Protection Measure (used packaging) 2011. The responsible parties are the Brand Owner (importers of the bags) and Brand Owner (trademark) per the Act. The risk to your customer is up to $3,200,000 and/or 5 years imprisonment in some States for inappropriate disposal or environmental harm from these bags.

What does the National Environmental Protection Measure (used packaging) 2011 (NEPM) and the Recycling and Waste Reduction Act 2020 (RWR) have to do with me?

The NEPM and RWR Acts are the Federal regulatory instruments that Brand Owners must satisfy. The RWR also outlines the timeline for the banning of exports of plastics and other waste.

When does the ban kick in?

The export ban started July 2021 for mixed plastics and for all other plastics July 2022.

How much does it cost? Who pays?

Our pricing policy is a uniform pricing model based on recovery and program costs. BBR charges the responsible entity the Brand Owners on a license and recovery basis. Brand Owners may absorb the cost or pass this onto their consumer.

How are the bags collected? And where?

BBR has National Collection Partners. They have the capacity to collect from every local government area in Australia.

Most of the bags will be collected directly from businesses (factories, farms, mines, etc). Additionally, Councils and community groups will provide drop off facilities similar to the Farm Waste Recovery model. These compounds will be serviced regularly and advertised where and when open. It costs the user nothing to drop these off as the cost is built into the stewardship fee.

What happens to the bags?

All bags are processed by Circular Communities Australia at their Toowoomba facility or other contracted processors.

What happens to non-BBR bags?

BBR will only collect bags that are part of the program. All other bags will not be collected. Non-BBR bags that arrive at drop off points will be advised to the Minister through his powers against ‘free riders’ and the bags may be returned to the Brand Owner for appropriate disposal.

What about old or legacy bags?

BBR will continue to collect these.

What do I get for the program fee?

- Federally Accredited Product Stewardship program

- Program that meets requirements of the National Environmental Protection Measure (used packaging) – compliments the National Packaging covenant

- Access to marketing and promotional material

- National coverage and online booking for users

- Reporting and auditability

- Choice to pass on the cost to consumers

- Regional drop off points, direct farm or business collections (where viable)

- Packaging collected for recycling satisfying Recycling and Waste Reduction Act 2020

- Reportable environmental outcomes: CO2e reduction, landfill replacement costs savings, and jobs generated.

- Plastic not entering waterways or being unnecessarily burned on farms

How does BBR calculate the Impacts? How is this validated?

Our validation: How we verify your data

All our data is derived from actual collections, for which every collection is recorded with the following information: Date; time; collector ID; Site address (and GPS coordinates); photo evidence; count or scan every brand owner bag by type (FIBC or sack) or weigh as a group every brand owner bag by type (FIBC or sack); and collection comments as necessary. This is verified by us and provided to you via your access to our database.

From the collected information we make an estimate based on best available assessments for carbon emissions, landfill cost saving and job creation relating to plastic recycling.

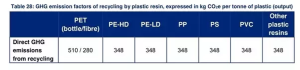

CO2e estimates are made using the calculations provided in the 2015 Deloitte report “Increased EU Plastics Recycling Targets: Environmental, Economic and Social Impact Assessment Final Report”

The calculation describes the differential between virgin resin production and recycled resin production and then adds the average sea freight CO2e from the point (India, China, Bangladesh etc) of manufacture to the point of use (and recycling).

16.14g CO2e per ton per km of freight is the accepted formula (statista.com and 8billiontrees.com)

Meaning for every kilogram of plastic we recover (for recycling) equates to 1.4678 kgs of CO2e reduction.

We have had this methodology reviewed and assessed by the University of Tasmania:

“Based on the information provided to me by Big Bag Recovery I am satisfied that the methodology applied to calculate environmental benefits that can be attributed to the scheme are reasonable and within a conservative range of performance.”

Professor Jason Smith

Head of Natural Sciences

University of Tasmania

Landfill cost savings is derived from advice from Department of Environment Queensland Assistant Director Kylie Hughes at $250m3. A compacted bale weighing 300kg is ~1m3, giving a compaction rate of 0.3t/m3. Bags not compacted and arriving at landfill would only be compacted by a dozer with a compaction rate 0.1t/m3. This is empirical and defendable.

It is worth noting that each State has different costs associated to creating new landfill and what can be put in them.

Circular economy jobs – This is based off 1 job per 100T of plastic from product stewardship to recovery, to resin production, to new product manufacture. The calculation is based on our known labour requirements to establish a resin/manufacturing facility. We know and can apportion FTE for product stewardship and collections, we also know that for a 1800T pa. resin plant 3 FTE x 8hr x 5-day shifts is needed to process, we also know that manufacturing also requires 3 FTE x 8hr x 5-day shifts are needed.

Links to the Acts

Additionally, every State and Territory has waste policies and regulations. There are 15 different departments in total.

About Us

Big Bag Recovery is part of the Industry Waste Recovery group. We are product stewardship professionals operating since 2015 with our program Farm Waste Recovery (now incorporated into Big Bag Recovery). We are dedicated to delivering environmental and social outcomes that are truly sustainable. Our team has over 80 years experience in Environmental and Operational management and genuinely love what we do.

Alliances and advisors

News & Events